Fluegas Desulphurisation

A Flue Gas Desulphurisation (FGD) system is a pollution control system that aims at decreasingthe exhaust of harmful SO2 to permissible limits. In many coal based power plants and industrial boilers, as a result of pet coke (or other forms of coal) burning, a residual Sulphur Dioxide SO2 is produced which is very harmful for the environment. As a result, Govt. Of India has set up a permissible limit for SO2 exhaust which is achieved by using a Flue Gas Desulphurisation (FGD) system. The FGD systems use alkali reagent for Sulphur Dioxide (SO2) removal. In addition to SO2 removal, the FGD system also treat chemicals like HCl, HF, SO3 and fly ash.

At Mago Thermal, our (NaOH Based)Flue Gas Desulphurisation system can have 98 – 99% capture efficiency.

Why Mago Thermal For Flue Gas Desulphurisation?

- Mago Thermal has years of experience in delivering FGD Systems across India.

- We provide customized Flue Gas Desulphurisation (FGD) System.

- Our FGD systems fulfills required norms of pollution control.

- Our Flue Gas Desulphurisation (FGD) Systems are cost effective with low capital investment.

- Strict quality control in installation.

- Highly experienced FGD Team.

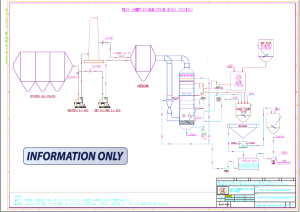

“SIEVENT” FGD SCRUBBER for 100 % PET COKE — FIRED BOILER.

1. PROPOSED SCHEME

The flue gases are passed through the proposed Scrubber (combination of Venturi and Sieve Tray) at the downstream of ESP and ID Fan .

The proposed Scrubber is designed to De-Sulphurize the Flue Gases in three stages, namely :

- PRIMARY TREATMENT.

- DRY SCRUBBING IN FREE BED ZONE.

- SECONDARY TREATMENT with NaOH Solution as a Solvent.

- REGENRATION SYSTEM

- PRIMARY TREATMENT : In Primary Treatment MAGO recommends using LIME STONE (CaCO3) in the furnace bed. Generally Lime addition is 2 % – 3 % of by Weight of the fuel quantity in the bed. This helps in recovering Sulphur in the combustion zone and with this SO2 is reduced to 5000 PPM – 8000 PPM in this zone.

CaCO3(solid) + SO2(gas) → CaSO3(solid) + CO2(gas)/

2. DRY SCRUBBING IN FREE BED ZONE:

In free board zone, we spray Ca(OH)2 through specially designed Nozzles. These Nozzles are placed at strategic locations in Free Board Zone to generate Dry Scrubbing action. In this zone, the SOx level is reduced to 3500 PPM – 5000 PPM.

Ca(OH) 2 (solid) + SO2 (gas) → CaSO3(solid) + H2O (liquid)

3. SECONDARY TREATMENT (with NaOH solution) :

Flue gases laden with 1500 PPM – 2000 PPM SOx passes through the Boiler Bank tubes, Economiser, APH etc and finally through ESP where SPM level is brought down. Partially CLEAN Flue Gases then pass through a Sieve Tray Scrubber through which NaOH solution is sprayed to absorp balance SO In this zone, the SOx is brought down to less than 50 PPM level.

2NaOH(solid) + SO2 (gas) → Na2SO3 (sol.) + H2O (liquid)

Na2SO3 (sol.) + SO2 (gas) + H2O (liquid)→ NaHSO3 (solid)

Here onwards the Scrubbed Gases are made to pass through a set of MIST Eliminator for separation of MIST from the Clean Gases.

DISPOSAL OF LEFT OVER

REGENRATION & USUAGE OF DOUBLE ALKALI.- FULLY AUTOMATIC

The Effluent contains ‘Na2SO3 / NaHSO3 / Na2SO4“ from the Venturi & the Sieve Tray Scrubber is PUMPED to Regeneration system. Regenration system consists of Mixing tank (For CaCO3 + Effluent Solution), Thickner & Vacuum Filter for Solid Recovery ( CaSO3/ CaSO4).

REGENRATION WITH LIMESTONE

CaCO3 (solid) + NaHSO3 (sol) → Na2SO3 + CaSO3. 1/2H2O (liquid) + ½ H2O + CO2

OXIDATION

HSO3 –+ ½ O2 → SO4+ H+ SO3 =+ ½ O2 → SO4 =

SULFATE REMOVAL AND NAOH RECOVERED

Na2SO4 + Ca(OH)2. +2 H2O → 2NaOH + CaSO4. 2H2O (sol)

INSTRUMENTATION

Adequate amount of System AUTOMATION has been considered for periodic PURGING along with field instruments to monitor the Pressure Drop and Temperature of the gas at Different Stages.

PROFORMANCE GUARANTEE

SO2 : less than 50 Ppm on continuous basis

COST OF SOX removal Shall Be Rs 0.20 / Kg of Steam generation.

We, at Mago Thermal, undertake Flue Gas Desulphurisation (FGD systems industries in Uttar Pradesh (UP), Maharashtra, Haryana, Punjab, Gujrat and other regions across India. For further details on Mago Thermal’s FGD Plants, call us or email us at marketing (at) magothermal.com